Custom Solutions specializes in the design and manufacture of leading-edge electromagnetic components. Power magnetics used in switch mode power supplies, linear power supplies and dc-dc converters are a major portion of the Premier Magnetics product portfolio. Switching power magnetics include: flyback transformers; isolation transformers; current sense transformers; EMI/RFI common mode suppression inductors and chokes and general purpose toroidal inductors.

Even with our extensive portfolio consisting of thousands of standard products, customers frequently approach us with their own, application-specific, and unique product performance requirements. In response to these inquiries, Premier Magnetics efficiently summons almost 30 years of experience providing World Class Design & Engineering expertise. Following our comprehensive process, we apply our experience toward solving each customer’s unique design & manufacturing challenges.

After years of providing extensive customer support from design to fabrication, today Premier Magnetics provides customers with two additional major services. These services include the Extrusion & Injection of Molded Plastics, and Full Circuit Assembly.

Premier Magnetics can provide Turn-Key assembly services to support your next project.

In addition to our standard product line that includes hundreds of UL and CSA recognized offerings, Full Circuit Assembly is a core capability that sets us apart from others in our field. Customers depend on Premier Magnetics’ World Class Design/Engineering expertise right down to the circuit level. This capability allows us to provide customized solutions for transformers, inductors, chokes, DC-DC Converters, and RJ45 Connectors with integrated magnetics, along with turn-key PCB assembly services. We support complete PCB assemblies that either integrate our magnetic components, or that utilize components from our clients’ bill of materials. Our experienced professional team makes the entire electronic assembly process simple and seamless by managing all aspects of your project process for you, including:

- Box builds

- Components and PCB procurement optimization

- Prototyping

- SMT and Through-hole designs

- Electromechanical assembly, component and wiring assemblies, and wiring termination

- Conformal coatings

- Functional testing

- Final packaging

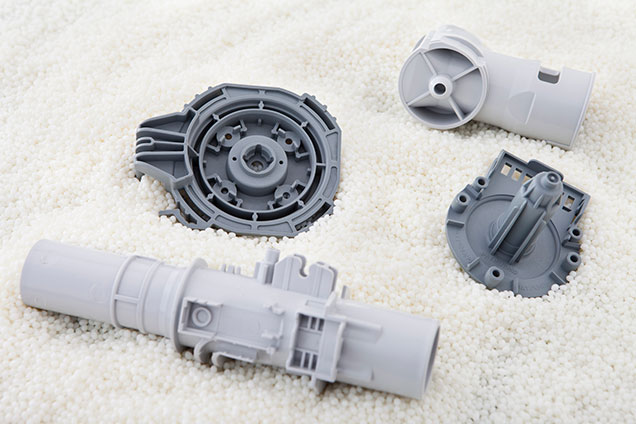

Moulding Capabilities

We also provide top quality Precision & Injection Molded products as a value added service to our 400+ OEM customers world-wide. Our molding capabilities include:

- Using injection molding presses that range from 40 to 2,400 tons

- A standard tolerance of +/- .005″ with even tighter tolerances available

- Molding parts ranging from under a gram to 8 lbs

- Both short and long production runs

- Precision molding of miniature as well as large components

Value Added Operations

- Assembly

- Cutting

- Drilling

- Ultrasonic welding

- Painting

- Silk screening

- Tap and screw instertion

- Spring insertion

- Part machining

- Sub and full assemblies

- Power Integrations + Premier Magnetics = Power Perfected

- Premier Magnetics Introduces Line of Frequency-Optimized Planar Transformers

- New Magnetics Solutions Support E-Bike Charging Reference Designs

- Premier Magnetics Line Filters Replace Discontinued Murata Components

- Whitepaper update v2: Using Common Mode Chokes to Reduce EMI/RFI

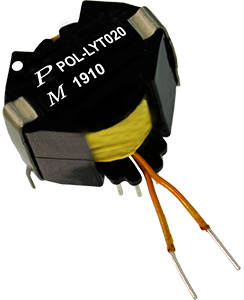

- Introducing Transformers Optimized for Power Integrations’ Latest LYTSwitch™ Line of LED Driver ICs

- Premier Magnetics announces its POL-HX Series of switch-mode transformers for the TOPSwitch-HX\99 line

- Product Announcement – Off-Line Switch-Mode LinkSwitch ® Transformers

- Avnet+Premier Transformer & Choke Service PPT